KLINGER SENTRY GASKETS

Metallic gaskets are used in high-pressure and typically hazardous pipelines constituting a huge safety risk in the event of a failure. For this reason, leakage testing before pressurizing the pipeline is paramount. However, traditional leak testing carries heavy production downtime and subsequent loss of earnings.

Traditional leakage testing

Leakage testing of a newly erected or amended pipeline is carried out by filling the pipeline with pressurized water or gas to monitor any changes in pressure that indicate a defective joint. The process is carried out in sections by blanking off an area of a pipeline using shutoff valves or blinds.

Depending on the valve location, it may be a large section of pipeline that must be pressurized to test a single flange connection and, in some cases, it is not practicable to leak test all of the joints. Leak testing large portions of pipeline is a time-consuming process, increasing production downtime and, consequently, induces economic loss.

Reverse Integrity Gasket leakage testing

Reverse Integrity Gaskets are designed to allow leakage testing to be carried out on individual flange connections to determine if tightness has been achieved before introducing internal pressure, and also allow monitoring of the joint throughout its lifespan.

SENTRY gaskets:

» Allows leak testing on individual flanged joints without the need to pressurize the full system.

» Leak test both the primary and secondary sides of the seal.

» Speeds up the leakage testing reducing plant downtime.

» Significantly reduces the volume of testing media required.

» Validates individual joint integrity at installation reducing the need to re-visit the joint.

» Joints can be tested and adjusted if leakage occurs, in one visit to the flange.

SENTRY RTJ

The Sentry can be used in both ring joint and raised face flanges. The Sentry RTJ gaskets are heavy-duty, high-pressure gaskets largely used in offshore petrochemical applications.

Ring Type Joints (RTJ) are precision-engineered components designed to be used in conjunction with precision-machined flanges.

The ring gasket is located within annular recesses in the opposing faces of the flanges. The ring gasket is compressed into the groove and the angled sealing faces deform to match the grooves and create a seal.

The pressure classes and geometries of the gaskets and flanges are given in the standards API 6A, ASME B16.20 and ASME B16.5.

Ring type joints can be supplied in various metallurgies.

SENTRY IK

Reverse integrity gaskets for flanges with cathodic protection.

The Sentry IK is specifically designed for applications where cathodic isolation is required or mitigation against galvanic corrosion combined with providing users the benefit of being able to install a gasket and test the integrity of the connection in the same operation.

SENTRY DS

The KLINGER Maxiprofile is a composite gasket, which utilizes a serrated metal core with a soft facing material. The Sentry designed for use in raised face flanges is based on a Maxiprofile.

The metal core is machined on each contact face with concentric serrations which provide high pressure areas, ensuring that the soft coating flows into any imperfections in the flange, even at relatively low bolt loads. The result is a gasket that combines the benefits of soft, cut materials with the advantages of seal integrity associated with metallic gaskets.

Expanded graphite is the most common facing material used for Maxiprofile gaskets. However, other materials can be used, such as PTFE for chemically aggressive duties or Mica for high-temperature duties.

Maxiprofile gaskets can also be manufactured from a range of core materials according to media compatibility and temperature considerations.

SENTRY SR

Reverse integrity gaskets for clamped connections

The Sentry SR is specifically designed for hub/clamp connections to provide reassurance that the seal ring has been installed correctly within the hub unit. Based on the original seal ring dimensions, the Sentry SR has been rated up to 5000 psi by global operators.

SENTRY GASKET LEAKAGE TESTING

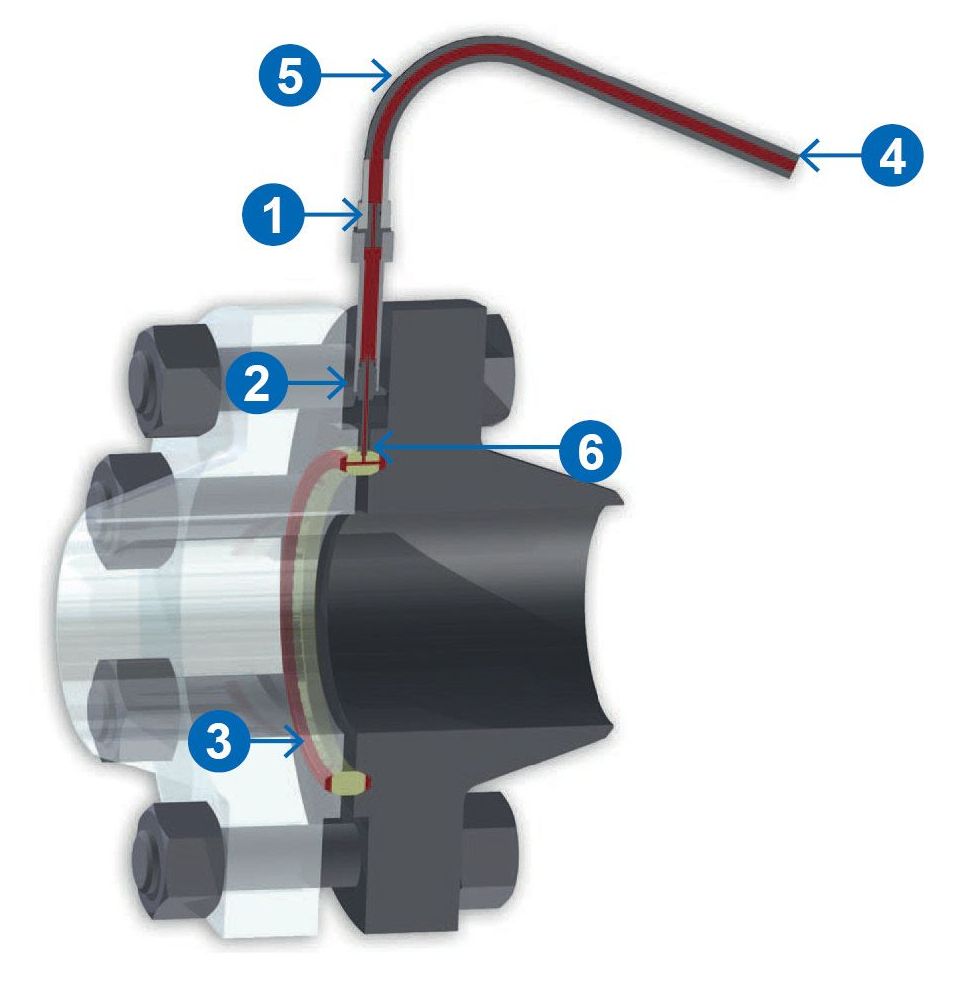

A KLINGER Sentry gasket incorporates a leak detection system

High Pressure quick release test plug connector

Quick-release connection between pressure equipment inlet and gasket test plug connector allows quick and easy attachment for testing.

Anti-Rotation Device

The duct comprises an anti-rotation device that sits within the intra-flange space. The device prevents rotation and bending of the testing duct preventing stress at the welds.

Pressurized Recesses

In the RTJ style, the pressurization occurs in the annular cavities above and below the gasket in the flange groove recesses. In the Maxiprofile style, the pressurization occurs in the annular space between primary and secondary seals.

Pressure Monitoring

Pressure changes within the sealed recess are monitored from outside the flanges via the test equipment. If the seal is sufficient, the pressure will be maintained. Conversely, in the event of a seal fault, failure to hold the pressure can indicate a leak path between the gasket and the recess, indicating intervention is required in that particular joint.

Pressurized Fluid Inlet

KLINGER hydraulic test equipment is designed to be compatible for use both on site and for subsea applications. Test Range 0-400 Bar.

Fluid Delivery Ducts

The tube extends from the gasket into the space between the flanges and is accessible from the outside of the pipe when the gasket is sealed in the recess. The tube allows fluid communication with a T-shaped channel within the gasket to allow pressurization of the cavities.

Post Leak detection

Blind Plug with Fire-Safe Seal

The blind cap cooperates with the connector on the duct to close the opening to the test cavities. The cap has a sealing member in the form of an annular packer enabling the gasket to hold fire-safe certification.

Blind Plug with Hex head for easy fitting

The Blind plug has a hexagonally-shaped recess compatible for use with torque tools such as an Allen key.

The Blanking cap must be applied at the end of the leakage testing procedure and can only be used once. If removed for retesting, the blanking cap must be renewed.

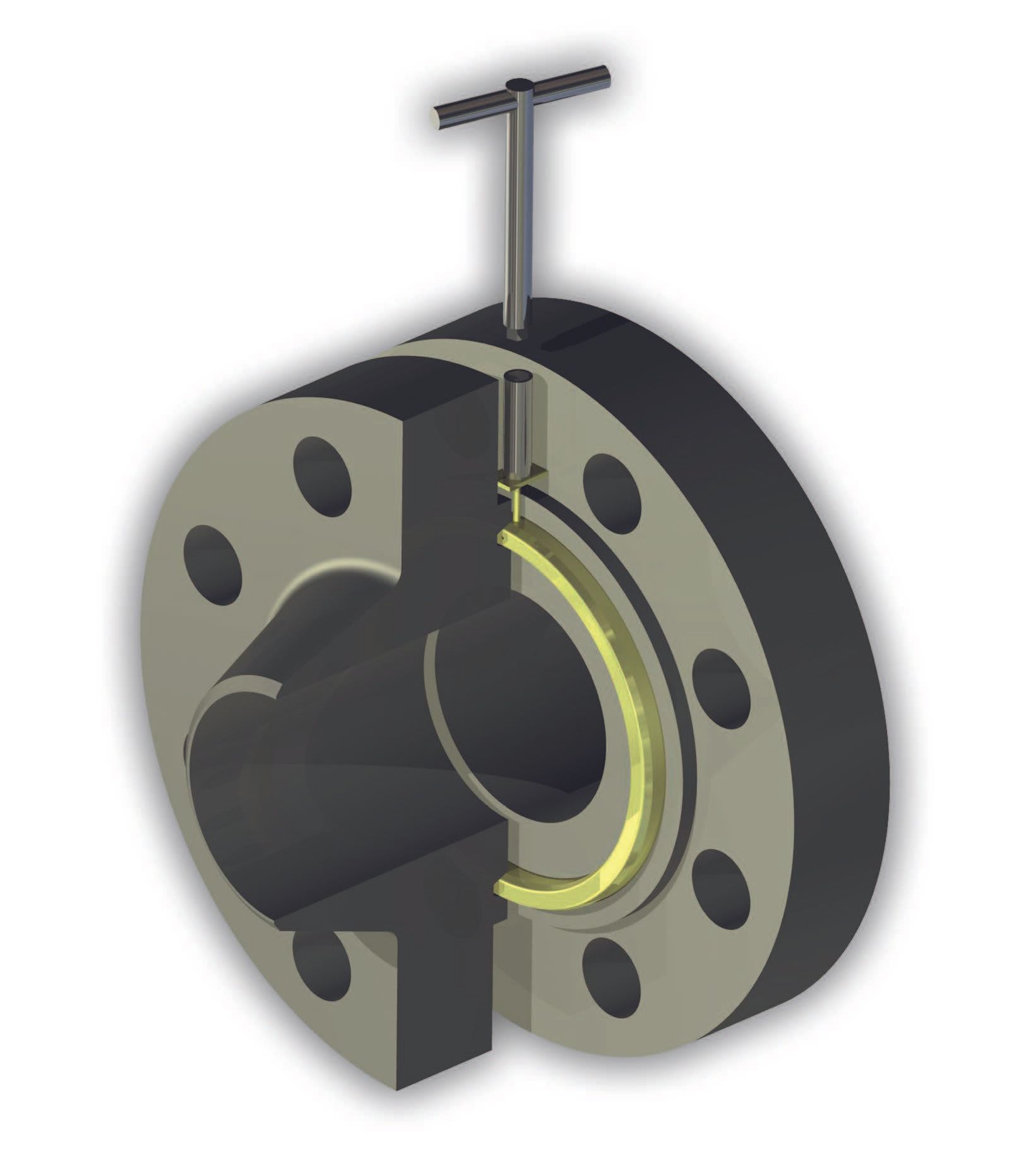

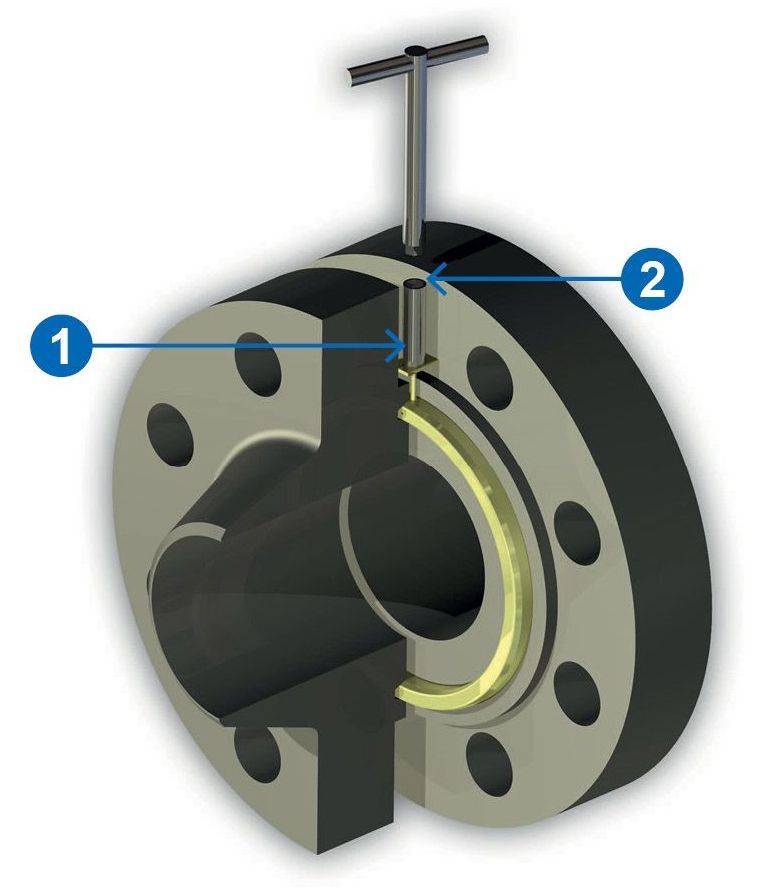

SENTRY GASKET INSERTION TOOL

KLINGER Gasket Insertion Tool (KGIT) allows safe and precise insertion of a KLINGER Sentry RTJ (Ring Type Joint) between two flanges, allowing a safer, easier and faster fitting process with minimal need for re-visiting.

The KGIT decreases the risk of injury to divers' hands and fingers as the engineered profile is designed to locate accurately within the lower bolts of the flange, ensuring the gasket sits correctly in the groove. With well-positioned holes designed to accommodate standard subsea tooling, the KGIT aids transportation and fitting. Flange alignment tools can be left in the flange as the gasket is fitted minimizing movement of the flanges, and ensuring there is no "bruising" or "pinching" to the gasket.

The KGIT offers improved flange makeup times and increased safety. The shape of the tool so prevents the handle from rotating in front of the stud bolts, ensuring the gasket doesn't need to be repositioned to add the remaining bolts.

Once installation is complete, the handle of the KGIT can be easily broken off giving access to the Sentry test duct. The tag can be retained for records. After a period of time, the KGIT corrodes away due to the cathodic reaction resulting from immersion in salt water.

Phone: +1 (800) 624-7074

All Rights Reserved | KLINGER GPI