SAFETY SPRAY SHIELDS

The innovative Safety Spray Shield design from Flangeguards. Representing over twenty years of experience and development, this new design significantly improves upon conventional shielding products.

ALL-PTFE. OUTLASTS CONVENTIONAL PTFE-COATED FIBERGLASS SHIELDS IN CORROSIVE ENVIRONMENTS.

ALL-316 ST/ST BANDING AND MESH. SUITABLE FOR HIGH PRESSURE AND TEMPERATURE APPLICATIONS.

SAFER

PDT technology makes Sureband THE most cost-effective shield design on the market. Be sure, be safe, choose Flangeguards.

QUICKER

No pull-cords. Quick fit connection cuts install time dramatically, saving time & money. Operators are more inclined to re-fit after removal.

BETTER

Best-in-class materials of construction and performance.

SAFER

PDT technology makes SUREBAND THE most effective shield design on the market. Be sure, be safe, choose Flangeguards.

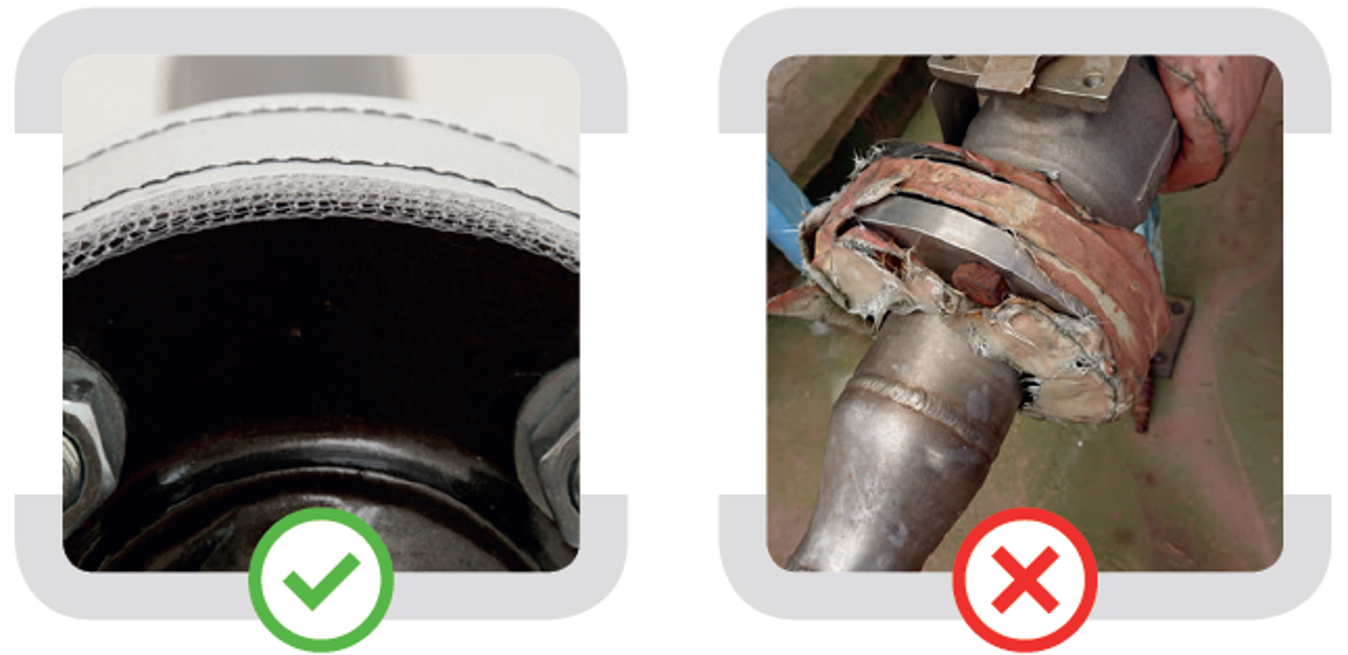

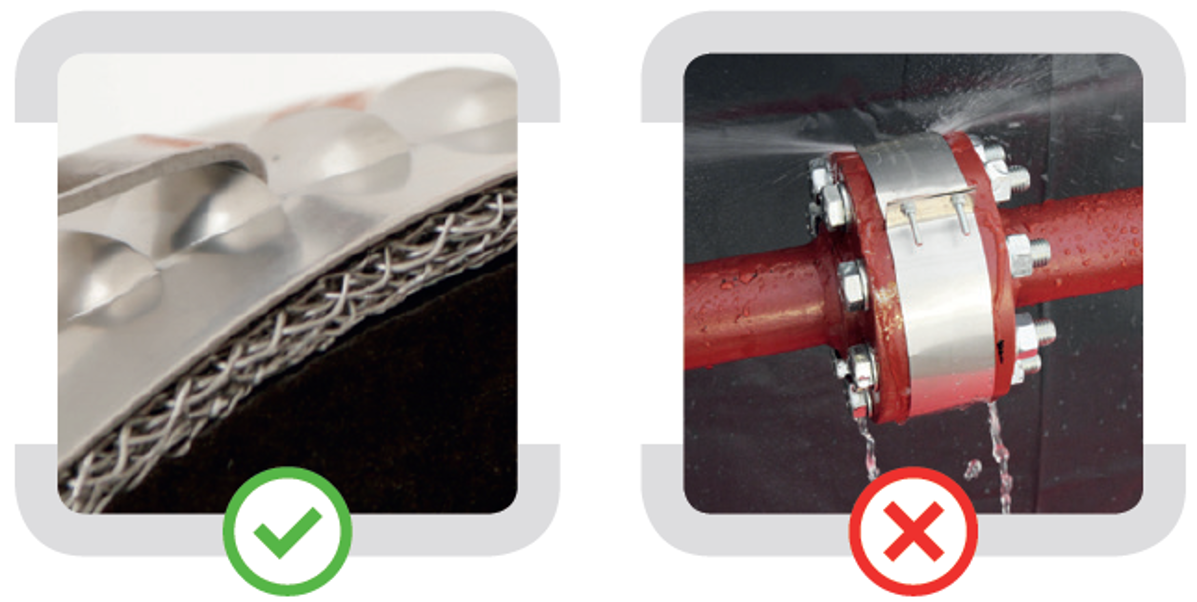

SUREBAND PDT (Pressure Diffusion Technology) uses a specially formulated multi-layered mesh that is held against the flange. The pressure is diffused in a controlled manner thus preventing the formation of a mist/vapor cloud. At the point of exit from the shield, the leak takes the form of a safe, vertical drip or stream.

Our leak testing facility has proven that pressure diffusion is required to prevent spray and mist formation. However, many shield designs have no diffusion – and this can actually create a worse leak than no shield at all.

QUICKER

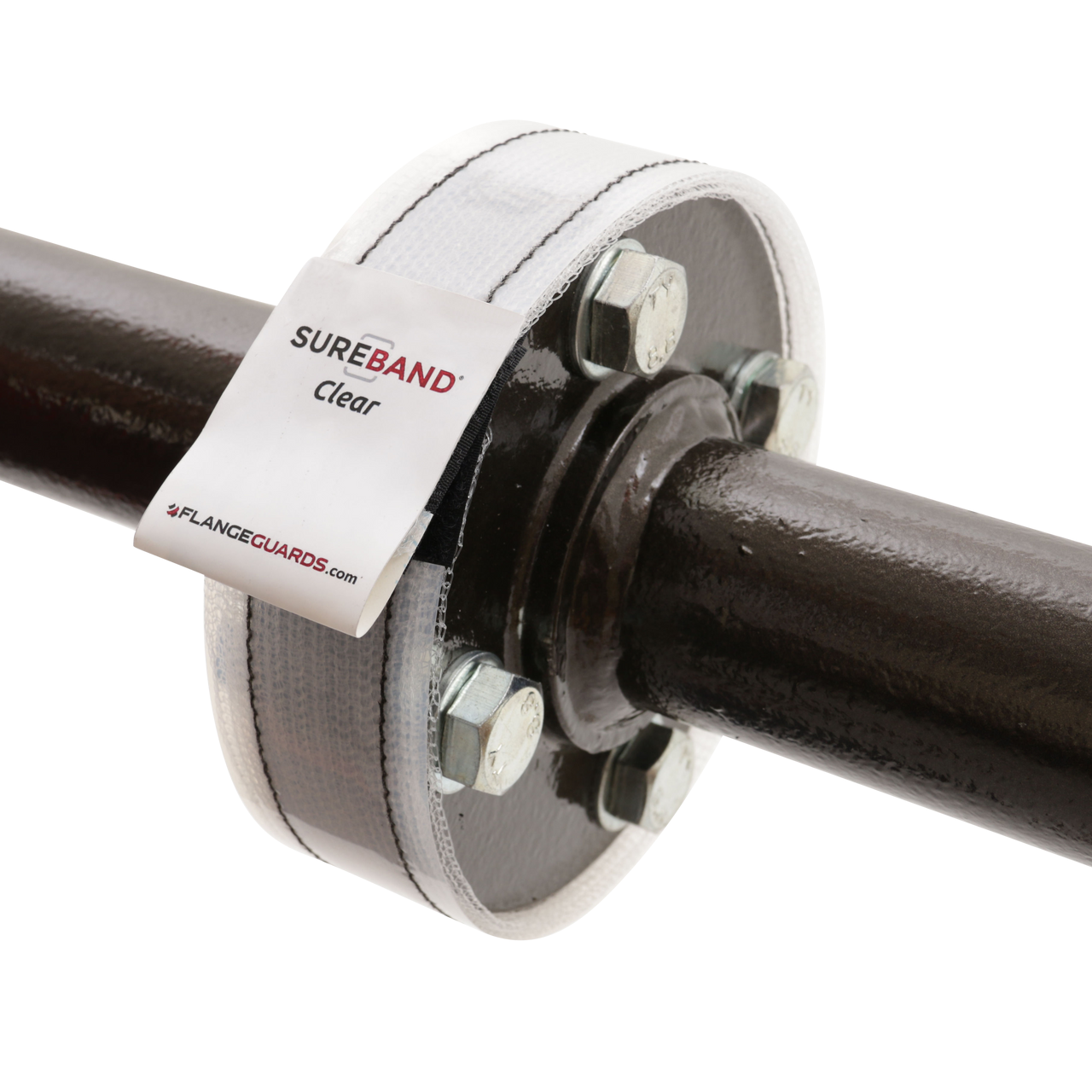

Our Quick-fit connection makes installation and removal of safety spray shields quick and simple

SUREBAND was designed with simplicity in mind. Unlike conventional "pull-cord" shields, no knots are required. This is a significant benefit, especially when removing shields - and tightly tied knots are typically cut, not untied.

The Clear shield uses a proprietary technical hook+loop connection (40kg lateral shear strength).

The Steel shield uses a quick connection latch which locks into one of 4 specially designed louvre slots.

Installation time can often cost more than the shields themselves. SUREBAND is fitted within seconds (rather than minutes). This saves time and money, whilst maintaining maximum safety.

Ongoing pipe maintenance requires shields to be removed. Gloves are generally mandatory, so pull-cord knots are typical cut off rendering conventional shields useless. With SUREBAND, operatives are much more likely to re-fit shields (shields are often used within hazardous area zoning calculations, thus failure to re-install the shields invalidates zone classification).

BETTER

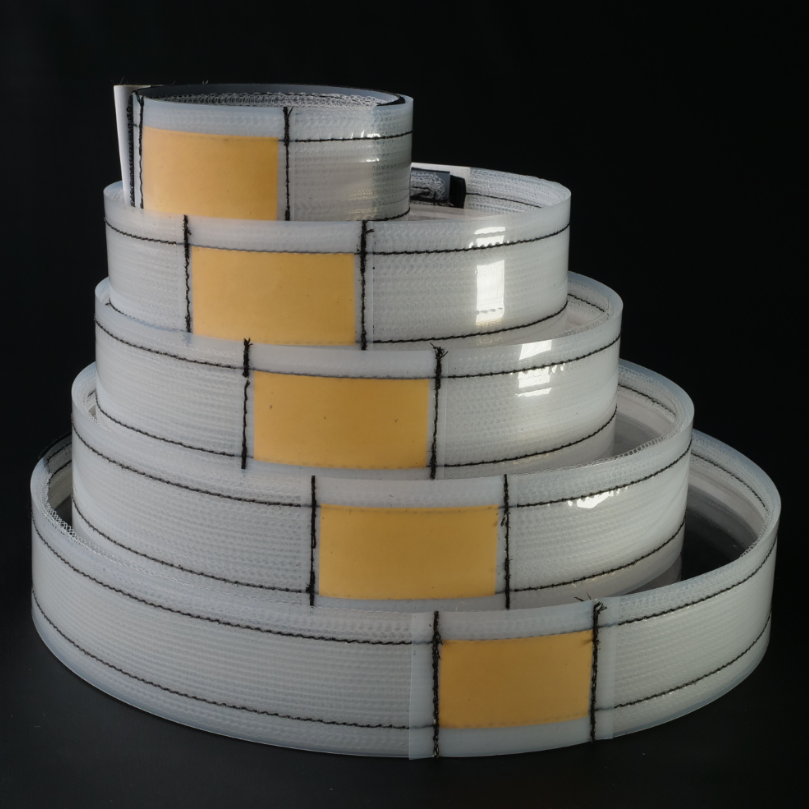

MULTI-SIZE FUNCTION Increases flexibility & reduces stock holding

The Multi-Size system means one shield fits multiple flange sizes. Only 5 shield sizes are needed to fit all 28 standard flanges between ½" and 6" pipe size (across multiple pressure classes).

This reduces stockholding & speeds up delivery dramatically. It also prevents fitting errors where site surveys are require (fixed size shields require precise flange measurement).

BEST-IN-CLASS MATERIALS Using highest quality materials, resulting in longest service life

100% ETFE and ECTFE. Conventional fabric shields are made from fiberglass coated with PTFE. Over time, with exposure to corrosive environments, the fiberglass is exposed and ultimately degrades. SUREBAND Clear contains no fiberglass, ensuring a considerably longer life span.

Comprising all-316 stainless steel outer band and inner, multi-layered mesh. SUREBAND Steel works effectively at high pressure and wide temperature ranges. The quick-connection latch makes installation simple.

Phone: +1 (800) 624-7074

All Rights Reserved | KLINGER GPI