VALVES

PISTON VALVES

Piston valves stand for excellent industry performance with their minimum maintenance requirements and production savings. KLINGER piston valves are characterized by a system of seals and rings that ensure tightness to atmosphere and thus prevents environmental contamination.

KLINGER has been at the forefront of piston valve technology since 1922. Featuring different types of connection - flanged, threaded, butt and socket weld ends - and both DIN and ANSI-compliant standards, KLINGER piston valves complete the wide range of KLINGER's industrial valves.

Piston valves are suitable to pressure Class 150 and 300, in sizes up to 8". Body materials are cast iron, carbon steel or stainless steel.

BALL VALVES

Our industrial ball valves are important components in process engineering systems of all main sectors for the maintenance of transport and production processes. The functional area of responsibility ranges from shutting off, throttling and regulating material flows (solid-containing, liquid or gaseous) in piping systems up to opening and closing processes in piping systems.

The sometimes extreme operating conditions (pressure, temperature, medium) and the safety requirements in the process and control technology require our detailed technical knowledge and application experience for the differentiated design and manufacturing of the industrial ball valves.

The KLINGER Intec ball valve range includes small bore quarter turn valves, soft seated or metal seated 2-piece valves, wafer valves, multiple port valves, sampling valves and 3-piece high pressure valves. A wide range of material options are available to suit any application.

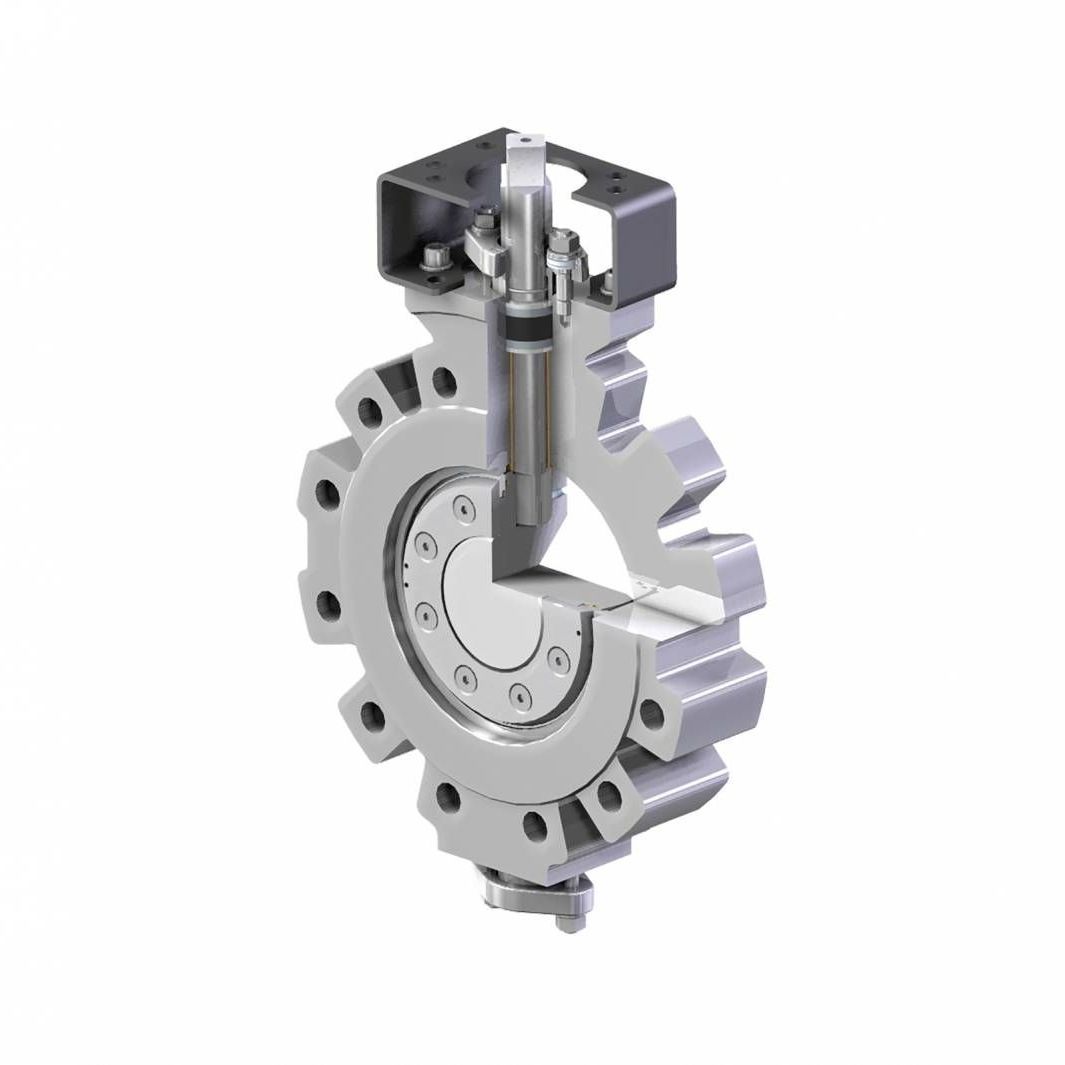

BUTTERFLY VALVES

Butterfly valves regulate or isolate the flow of a liquid medium by means of a rotatable disk. Similar to ball valves, butterfly valves are also characterized by their quick operation. As a quarter-turn valve, fully opening or closing the valve is achieved by rotating the disk a quarter of a turn.

Quadax® butterfly valves can be supplied in various styles and configurations up to 40" nominal bore sizes and are suitable for pressure ranges up to Class 900. The quadruple offset design offers many advantages including the reductions of friction, flow restrictions and stem torque.

STEAM TRAPS

Thermodynamic steam traps are a robust, low-cost option for condensate drainage in steam distribution lines. They are designed with three outlet holes and a stable operation disk which ensures a longer life to the steam trap.

Thermostatic steam traps are a simple and robust solution for purging condensate in small equipment. The thermostatic actuation occurs through a bi-metallic device that guarantees efficiency and durability.

Steam traps come in a variety of connection options, including DN 1/2", 3/4" and 1" NPT or BSP thread, making them compatible with a wide range of fluid control systems.

Phone: +1 (800) 624-7074

All Rights Reserved | KLINGER GPI